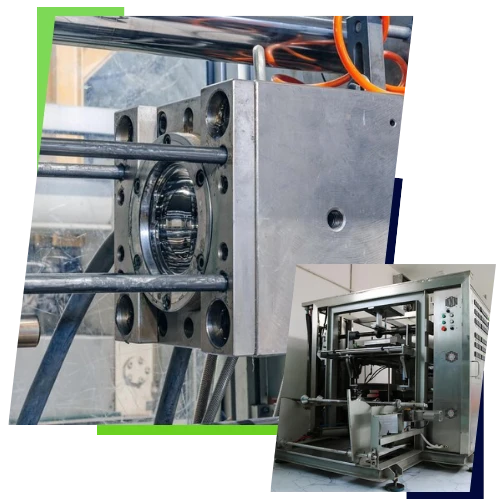

Plastic Injection Moulding

End-to-End Plastic Injection Moulding Solutions

Expertise That Powers Innovation

Our strength lies in a highly skilled team of engineers — Process, Plastic, Quality, Tooling, and Project Engineers — who bring hands-on expertise in plastics engineering and moulding. With deep knowledge of material behavior, mould design, and tool maintenance, we help customers achieve accurate results in every project. By combining creativity with technical precision, we can manufacture components and assemblies that meet demanding industry standards. Whether it’s maintaining complex moulds, minimizing downtime, or scaling production, we ensure continuous flow and consistency across every production batch.

Sustainable Manufacturing, Certified Standards

Beyond quality and precision, we are committed to eco-friendly and compliant practices. Our production follows global standards such as:

- RoHS – Restrictions of Hazardous Substances

- WEEE – Waste Electrical and Electronic Equipment

- REACH – Registration, Evaluation, Authorization, and Restriction of Chemicals

- IMDS – International Material Data System

With value-added services like finishing and assembly, we act as a single-source supplier, reducing waste, rework, and overall costs. By embracing the “Go Green” movement, we help businesses achieve high-performance results while supporting a cleaner, sustainable future.

Precision CNC Machining

Precision CNC Machining Services

At Shefield, we deliver high-precision CNC machining solutions with a proactive, results-driven approach. Equipped with the latest CNC and conventional machines, our facility is capable of producing complex and highly accurate metal components and assemblies with efficiency and cost-effectiveness. From concept to commissioning, we offer full-cycle machining support — design, prototyping, tool design, validation, and production — ensuring that every part is manufactured to the highest standards.

Expertise Across Materials & Processes

Our strength lies in a skilled team of Mechanical, Tooling, Quality, and Project Engineers, who bring hands-on experience in precision machining of metals and plastics. We work with a wide variety of materials, including:

- Stainless Steel (AISI 303, 304, 410, 420, 17-4PH, etc.)

- Non-Ferrous Metals (Brass, Aluminum, Copper)

- Carbon Steel, Tool Steel, and Low Carbon Steel Grades

- Plastics (rods, sheets, custom components)

Our services extend beyond machining, covering heat treatment, stress relieving, surface coating, forming, and fabricating of both ferrous and non-ferrous metals. With turnkey capabilities, we deliver everything from single components to full assemblies tailored for diverse industries.

Quality, Reliability & Material Competence

We believe that successful machining begins with the right material selection. Our team has a deep understanding of material properties — from composition and microstructure to geometry and mechanical performance — enabling us to design machining processes that achieve superior product functionality.

With advanced quality control systems, we ensure consistent production, minimize scrap and rework, and guarantee on-time delivery. By combining technical expertise, robust processes, and value-added services like finishing and assembly, we act as your trusted single-source machining partner.

Mould Manufacturing

Advanced Tooling for Precision Moulds Manufacturing

Tooling is the foundation of successful moulding, and at Shefield, we specialise in designing and managing complex injection moulds with high precision. From hot runner systems to intricate core pulls, our tooling programs are built to ensure defect-free, consistent production. With decades of experience and a global footprint, our team has worked with advanced moulds across Germany, Italy, Australia, Japan, Taiwan, Korea, and China — delivering exceptional performance and long-lasting durability.

Expertise in Tool Development & Management

Our tool development engineers play a critical role in guiding projects from concept to completion, ensuring quality and efficiency at every stage. We manage tooling programs with full control — whether in-house or with global partners — to meet the highest standards of quality, cost, and timelines.

Key focus areas include:

- Tool certification and validation

- Mould flow analysis

- Evaluation and corrective action planning

By leveraging our expertise in moulding, product development, and materials, we provide valuable insights at the design stage to enhance manufacturability and reduce lead times.

Wide Range of Tooling Capabilities

We offer a comprehensive portfolio of tooling solutions to meet diverse industry needs.

Tooling options include: Proto moulds, single & multi-cavity production moulds, hot runner systems, shuttle moulds, cartridge moulds, unscrewing moulds, and more.Material expertise covers: Aluminum (proto moulds), soft steels, hardened tool steels, beryllium inserts, and advanced finishing operations such as mirror polishing, texturing, and specialized tool coatings.

Our strong partnerships with local and offshore toolmakers allow us to offer cost-effective outsourcing options, while maintaining strict control and quality consistency.

Integrated Development & Design Support

From the earliest stage of product design, we actively collaborate with clients to determine manufacturability and performance criteria. Our complete tooling development structure includes:

- Evaluating requirements & specifying moulds

- Mould design and approval

- Tool building & trial samples

- Tool validation and process parameter freezing

- Transferring data to APQP documents

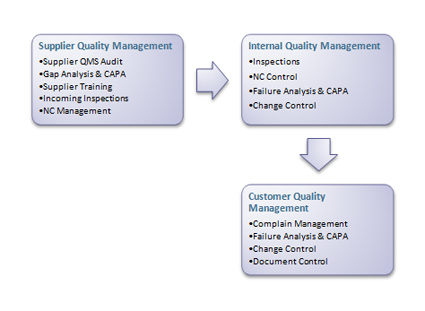

Quality management

We focus on the “prevention rather than the detection” To achieve this, we follow systematic method, – Advance Product Quality Planning – and assign a Quality Engineer to work with a project team through entire plan & define, design, manufacturing and validation cycle. Specifications for functional testing and gauging systems are established during project initiation stage. Dimensional requirements, aesthetic standards and special characteristics, SPC techniques to be used, are also defined. Once the mold is built, we conduct a process capability study on CTQs in addition to complete inspection layout to assure the specifications and requirements are on target. Some of key activities that we perform to assure quality before-hand include,

- Review all customer specifications

- Cross-functional project reviews

- Assuring all inputs to the specification

- Process and material flow charts

- Review & Approvals of tool design concepts

- Process Failure Mode and Effects Analysis (PFMEA)

- Identifying project related training needs

- Measurement System Analysis (MSA)

- Pre-production Control Plans

- Product and process capability analysis with defect detection

- CAR management

- Monitoring PPM level

The base of any quality product starts with the quality materials going into it. To ensure good quality material on time, we follow systematic vendor development & management plan. Our robust system helps us in development of suppliers which is a critical aspect of achieving a consistent product.

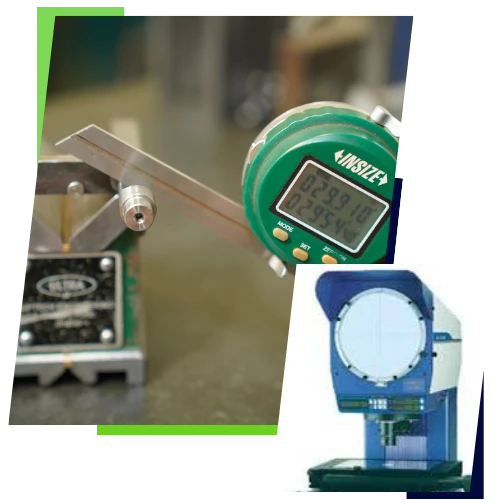

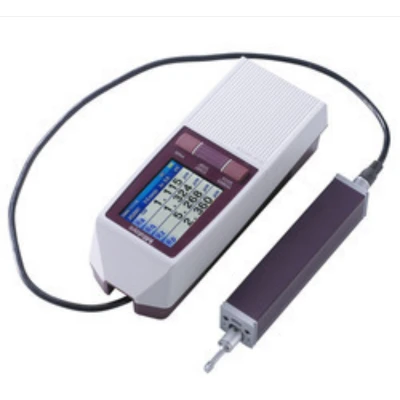

Metrology

In addition to complete layout inspection, we do in-process periodical inspections for critical characteristics of the product. This necessitates most consistent and accurate measurement techniques. To support our inspection capability per quality plan we have Precision measuring instruments that includes,

Facilities

Inspection Facility:

Precision digital measuring instruments

- Profile Projector

- Height Master

- Surface Roughness Tester

- Air Gauge

- Digital Caliper : 200 to 1000 mm

- Digital Micrometer: 25 to 150 mm

- Slip Gauge

- Thread Gauges

- Radius Gauges

- Filler Gauges

- Dial Indicator Gauges

- Combination Set

- Depth Gauge

- Surface Comparator

- Hardness Tester

- Push Pull Meter

- and all other related auxiliaries.

Quality Records:

Few of the important quality records that we maintain are,

- In coming material test results

- In process inspection results

- Pre shipment inspection results

- Tool history records

- COAs

Raw Material Testing:

- Spectro Analysis

- Tensile Test

- MFI

Specialize Product Testing:

- Helium Leak Testing

- Magnetic Partical Testing (MPT)

- Hydro Testing

- Non Destructive Test (NDT)

Design and Development

“The Advantage of Cost and Quality is never an Accident; it must be intentionally designed Into the Product.”

“Design for cost reduction, design for manufacturability, design for performance.”

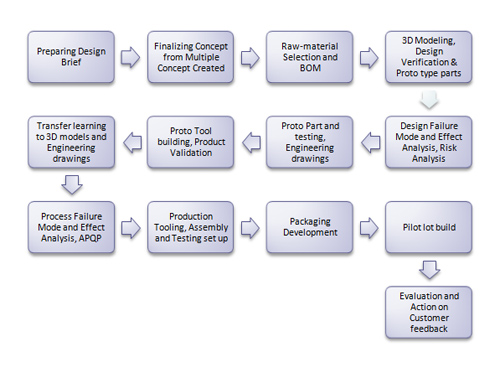

One of our strength is to take an idea through concept to engineering drawing, prototypes, validation, tool design and manufacture of final components and assemblies.

Our project team manages project from Design through Product Validation. Innovation is a significant by-product of Shefield’s expert development. Any innovations developed by Shefield Technoplast during work on your product belong exclusively to YOU, the customer.

Shefield brings a wealth of design assistance combined with a disciplined manufacturing process that can turn a brilliant product idea into an enormous commercial success.

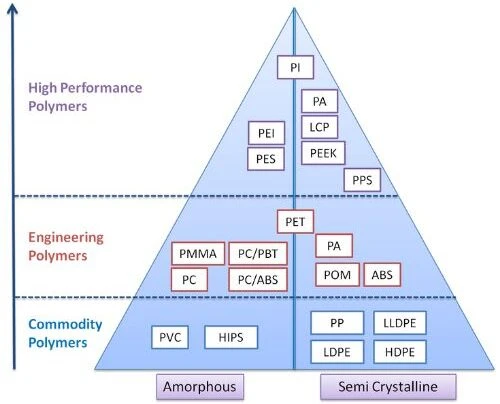

Our team ‘Knows’ Plastics, and knowing Plastics In-n-Out is a foundation for robust designing of plastic component.

Complete in-house plastic injection mold design. Stringent monitoring and control of the design and manufacturing process for outsourced activities.

Engineering Services that we offer are,

- Mold Development & Validation

- DOEs

- Reliability & risk Analysis

- Molding Process Design

- Gauge Design & Development

- Packaging Design Assistance

- DQ process validation

- Concept Creation

- Prototype Product (SLAs)

- Product Design Assistance

- Material Selection Assistance

- Mold Design

- Mold flow analysis

New Design Process Flow:

Sometimes you do not have or have old hard copy drawing of the components. Our technical expertise comes to your rescue for reverse engineering of the product and creates latest CAD drawing. Our Plastics and Tooling expert can also help programming improvement plan before we proceed for mold building. Using either our internal resources or long-term strategic relationships we can offer complete product design and services using professional CAD platform.

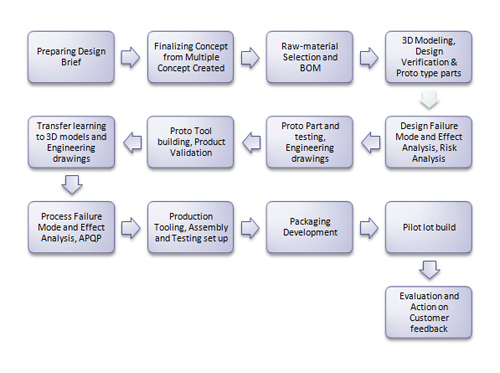

Reverse Engineering Design Process Flow:

Working closely with customers from concept design phase, we have been able to help optimize the design to achieve,

- Full functionality

- Cost reduction

- Faster time-to-market

- Ease of Assembly

- Improved Performance

- Increase Aesthetics

- Intended product life

Assembly

“Adding Value is our strength”

“Providing innovative solutions that add value to your product is our continuous endeavour”

Shefield offer a complete line of secondary and contract manufacturing capabilities. From simple assembly of mating components to complete turnkey assembly project of high precision complicated assemblies.

We also offer a wide variety of value added services that can save you time and money. Our manufacturing and contract capabilities include,

- Prototyping

- Laser Etching

- Hot Stamping

- Pad Printing

- Screen Printing

- Solvent Bonding

- Gamma Sterilization contracts

- Blister Packaging

- Static Elimination

- Product Testing contracts

- Ultrasonic Welding

Our value-added custom injection molding services are designed to provide end-to-end solution, including product concept and design capabilities as well as consultation on,

Material suggestion for optimum balance between cost and product performance.

- Prototyping

- Steel-to-plastic injection molding conversions

- Process-improving secondary equipment capabilities

- Superior quality control involving specific testing, evaluation, and calibration of all parts, equipment, and procedures

“Adding Value is our strength”

Shefield offer a complete line of secondary and contract manufacturing capabilities as a value addition to the product. From simple assembly of mating components to complete turnkey assembly project of high precision complicated assemblies.

Our value-added custom metal machining services are designed to provide end-to-end solution, including product concept and design capabilities as well as consultation on,

- Material selection

- Prototyping

- Superior quality control involving specific testing, evaluation, and calibration of all parts, equipment, and procedures

We offer comprehensive precision machining and finishing services, as well as assembly of diverse components into complete products or systems. Through value-added options, such as assembly we are able to provide consistent reliable quality and on-time delivery at a competitive cost.

As a drive to provide one stop solution, not only do we produce parts to exact tolerances, but we also assemble products or systems with the care and attention to detail customer require. By offering product assembly services, we are able to provide customers with the fast turnarounds they need to market effectively.

Quality redundancies are implemented in this final phase of production for the best possible performance of your product or system.

We have segregated assembly area with fully equipped work flow stations. All stations have an assortment of tools to perform various assembly operations required. Trained and certified employees, who adhere to strict work instructions. Our employees are dedicated to ensure that product performs as efficiently as possible and as a result strive to meet consistent high quality standards.

Assembly done in-house means that your product or system is assembled with the same commitment to quality as the individual parts we produce Additionally, we offer a wide variety of value added services that can save you time and money. Our manufacturing and contract capabilities include,

- Heat treating

- Sand Blasting

- Welding

- Grinding

- Honing

- Blister Packaging